Techmelt Refiner Plates and Conical Fillings

Conical Fillings

Products

Refiner plates and conical fillings TECHMELT: bars up to 1 mm thick, perfectly aligned.

Constant and uniform hardness. Alloys suitable for the processes of refining.

Heat Treatment and homogeneity in the forming of the metal, avoiding porosities.

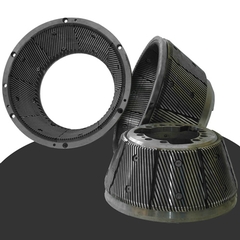

Exchangeable Segments for Conical Fillings TECHMELT ® |

||

This is a new system, much more rational and economic. After use, only the segments of bars are replaced while maintaining the same basis. |

||

Characteristics |

||

The set of conical fillings is composed of three cones axially aligned: |

||

|

- |

A central cone rotor (rotating) coupled to the engine and possesses segments on the outer face and on the inner side. |

|

- |

An external cone fixed with segments on the inner surface, in concordance with the external segment of the cone rotor; |

||

- |

An internal cone fixed with segments on the outside, in accordance with the internal segment of said cone rotor. |

Advantages |

||||

The exchangeable segments may be replaced in the case of wear and tear by the constant use and recycled. |

||||

The replacement of the segments does not imply the disassembly of the machine, simply by removing the screws that fix the cones, releasing the segments worn out and put in their places the new segments. |

||||

This operation is carried out fairly easy and quick, and there is no loss of productivity. With these advances, we have three primary advantages in relation to the conventional system: |

||||

1. |

Significant reduction in the prices of the conical fillings, by use of the base (molten material and machined); |

|||

2. |

Range of metal alloys with hardness greater than the re-rolled stainless steel wich reflects in economy of energy, by using shorter bars; |

|||

3. |

Conical Fillings with bars from one millimeter thick, allowing very low intensities. |

|||